Photostory #511: Canadian Engineers Invent Anti-Oil-Pollution Device

Photographers

,

,

Maker

National Film Board of Canada

Release Date

October 1, 1970

Collection

CMCP fonds

Credit Line

Canadian Museum of Contemporary Photography fonds, National Gallery of Canada Library and Archive

Main Text

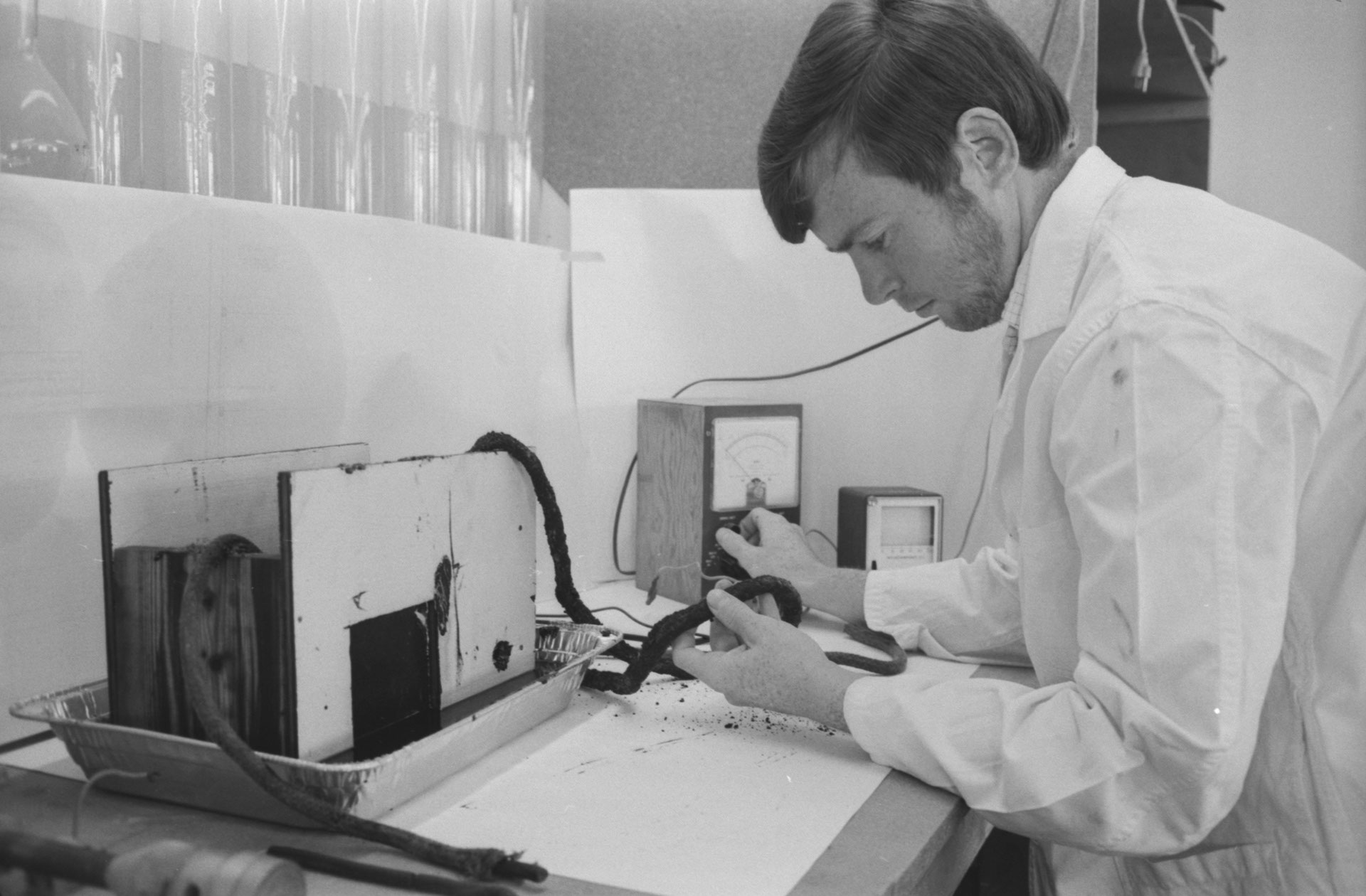

In progress Photostory 6/6 : Oil disasters along the sea coasts have made the public strongly aware of the far-reaching effects of this sudden and menacing form of pollution. On land the same type of pollution is often more insidious, starting unseen as a leak in an underground pipeline or tank and continuing for weeks or months before being detected. For the surrounding area this may mean oil-polluted groundwater, wells, streams, lakes and rivers. And for the pipeline operator it may mean responsibility for damage, economic losses of oil and disruption of service. _x000B__x000B_In many cases such leaks are too small to be even suspected. But over long periods of time the leakage builds up enough to make its presence known through pollution. Even then finding the location of the leak is a lengthy and costly task. _x000B__x000B_For five years a private company of consulting engineers in Ottawa sought a solution for this growing problem. First they decided on an idea in theory. They visualized two thin copper wires embedded in a cable made of a substance soluble in oil. They reasoned that if such an electrified cable was laid alongside an underground oil pipeline at the time of installation, any subsequent leak, no matter how small, would immediately begin to dissolve the insulating substance of the cable. This would produce a short-circuit in the cable at the point of the leak, sound an alarm at the nearest control point and the electrical resistance would pinpoint the position of the leak. Thus a repair crew could immediately uncover the pipe at the point indicated and repair the fault before any great damage was done. _x000B__x000B_Theoretically, this simple idea was sound. In practise, it was just the beginning of a long search for the engineers of Butts, Ross, Magwood and Hall Ltd. _x000B__x000B_The problem was the insulating substance between the two wires which was to dissolve when soaked in oil. Some materials tested melted too easily in any stray spot of oil, some took too long to avert major damage. Some were too soft so that the filling in of the pipeline trench compressed the wires together and gave false alarms. But at last the right material was found. Tests in the laboratory showed that within 24 hours of being soaked in oil a definite warning registered on the monitoring graph. The problem was solved. _x000B__x000B_Almost immediately local municipal authorities have ordered its installation alongside the feeder pipelines that supply furnace oil to houses in the new subdivisions. Meanwhile the use of the oil-leak detection cable for monitoring long-distance pipeline arteries (often checked for leakages by costly aircraft patrols) is being tested as also its use around gas station storage tanks. _x000B__x000B_The development of this warning cable, no thicker than ordinary domestic electrical wiring, has provided those responsible for transporting oil with a safeguard which will doubtless save many a pollution problem in a world increasingly conscious of environmental values.

Subjects: